Technological development for the production of adsorbents, catalysts and ion exchangers that leverage the maximum potential of materials

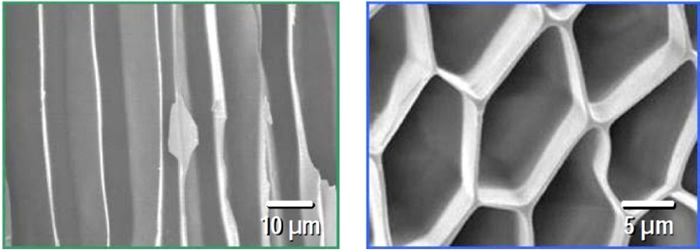

A micro-honeycomb monolith structure formed using the Ice Template Method

Prof. Shin Mukai of the Graduate School of Engineering has developed the Ice Template Method as a technology for the formation of micro-honeycomb monolith structures using directional freezing of wet gel, a precursor of porous materials. This study was supported by the Industrial Technology Research Grant Program under Japan’s New Energy and Industrial Technology Development Organization (NEDO).

With low resistance to fluids, the monolith structures formed leverage the maximum potential of the materials. Since low-priced raw materials are readily available and templates are safe and easily removable, this is a low-cost (only a fraction of the cost of traditional methods), environmentally friendly technology for producing porous materials such as adsorbents, ion exchangers, and catalysts.

To commercialize the Ice Template Method, Prof. Mukai is seeking partners for long-term joint development of completely new forms of materials to establish a track record of material research results.

Specifically, the key research target is to prepare product specifications at clinical study level with businesses that have a track record of product/technological development for adsorbents, ion exchangers, and catalysts as well as for gels used in bio engineering. Specimen prototypes will also be designed to study the feasibility of commercialization.

Contact information:

Prof. Shin Mukai

Graduate School of Engineering, Hokkaido University

E-mail: smukai@eng.hokudai.ac.jp